background

A municipal wastewater treatment plant (WWTP) in Far North Queensland had an average daily inflow of 1.8 – 2.0MLD, which can increase threefold during wet weather events. The plant also receives high fats, oils and grease (FOG) content from a concentration of eating establishments in its catchment. Foaming caused by Nocardia bacteria was a constant problem in the SBR basin. WTS was engaged to identify the problem and deliver a solution to control the foam problem and improve the plant’s performance.

approach

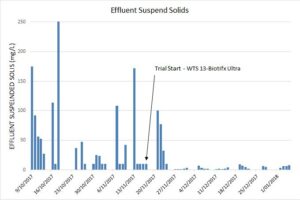

The objective was to demonstrate improved plant performance and decrease Nocardia foaming & effluent suspended solids. Historical data was available from the plant, including effluent suspended solids, SSV and other plant performance parameters. Understanding that the problem was a biological imbalance, WTS trailed a biological improvement program.

solution

WTS 13-Biotifx Ultra was slug dosed to the system with a large initial dose followed by a small ongoing daily dose at the inlet structure of the plant Monday – Friday. As no operators worked weekends, double dose was administered Friday afternoon.

The WTS 13-Biotifx Ultra showed a significant decrease in Nocardia bacteria foaming and a vast reduction in effluent suspended solids. Additional operational improvements were reduced sludge yields, decreased SVI 60 and faster recovery from septic influent events.

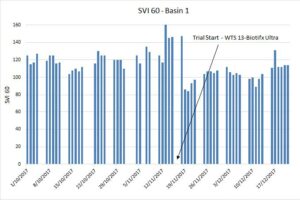

SV 60 was also reduced during the trial indicating a better settleability and more compact sludge in the SBR.

|

|

| Thick layer of foam Nocardia prior to application of Biotifix program | Foaming greatly reduced following application of Biotifix program |

results and benefits

- Reduced Foaming. Leading to better clear water decanting during the settling period in the SBR basin.

- Suspended Solids. Effluent suspended solids were greatly reduced and more consistent.

- SVI 60 reduced indicating a better settleability and more compact sludge.

- Better recovery. Septic influent events recovery time reduced from 2-3 days to 1 day.

- Sludge wasting time. (WAS) reduced from 80 minutes to 65 minutes

|

|

| A large reduction in effluent suspended solids was noted when comparing before and after the trial | SV 60 was reduced during the trial indicating a better settleability and more compact sludge in the SBR |