background

Over the course of three decades, including ownership changes, WTS has supported an ethanol production plant in Far North Queensland with treatment of their cooling system. Large industrial cooling systems employing cooling towers usually require disinfection to protect against dangerous bacteria including Legionella. They also needed to protect the system against corrosion and scale build-up which can limit the asset’s life and throughput capacity.

The tropical environment creates ideal conditions of biological growth. This combined with the typical water sources in Far North Queensland often makes for challenging water chemistry. Indeed, this case of industrial cooling towers operating in this environment required a unique solution and a considered approach to applying chemistry solutions, with WTS is best suited to provide. This site previously had significant scale challenges which inhibited production capabilities.

approach

Over such a long partnership with our client, we have had various levels of involvement in their water infrastructure.

WTS applies a tried and tested four-phase continuous improvement process to every scenario where we use scientific method and real-world results to drive the choice of solutions and optimise their application for efficacy and efficiency.

Solution

- WTS first began treating the Cooling Towers in 1993 with Chlorine Dioxide

- ClO2 is much more effective and safer to handle than Chlorine gas in these applications.

- ClO2 also controls biofilm formation

- ClO2 promotes reduced corrosion rates, particularly in copper containing alloys, e.g. in condensers.

- In 1994, WTS trialled against a multinational competitor for corrosion inhibition treatment and was subsequently awarded the contract on a 22% reduction in cost and 62% reduction in corrosion rate.

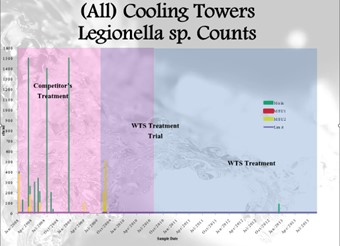

WTS has continued to support the client through several competitive contract renewals, aside from a period from 2005-2010. Following this period, WTS was able to demonstrate superior performance and was re-awarded the contract.

results and benefits

- Confidence. WTS has worked with the client for such a long time that we have an intimate knowledge of the plant’s history and characteristics, best placing WTS to make sure our water treatment solutions are as effective and cost-efficient as possible

- Compliance. WTS has demonstrated our capability to keep bacteria under control with EPA compliant solutions

- Demonstrated success. Going through a period of 5 years where a competitor ran the treatment programs, as well as winning several contract negotiations reinforced the value of WTS’ solution application abilities to the client.

- Productivity. Maximised productivity associated with properly controlled scale maximising cooling capacity

- Asset Condition. Site condition is excellent due to minimal corrosion due to chemicals and ongoing monitoring program.