background

A construction site was facing challenges with effective solid-liquid separation in their settling pond. They required a solution to meet environmental regulations and maintain efficient water management practices. The settling pond was struggling with solid separation issues despite the site purchasing WTS 8-23 and applying it themselves.

The client engaged Water Treatment Services (WTS) to define the optimal dosage range to achieve optimal solid-liquid separation to get their water back within compliant specifications.

This case study underscores the importance of tailored testing methodologies and the criticality of the correct application of chemical solutions in optimising water treatment for specific applications, ensuring compliance with environmental standards and sustainable construction site practices.

approach

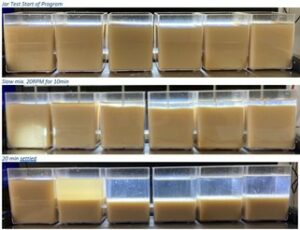

WTS’ water treatment experts took samples from the pond to the lab and conducted jar testing using WTS 8-23, which was already known to be the best chemical for the application.

The testing spanned a dose range from 180ppm to 260ppm, giving our scientists opportunities to determine the most effective dosage for solids settling in the settling pond. Within the identified dose range, the turbidity was significantly reduced, but an optimal point was found.

WTS solution

The 240ppm dosage, emerged as the most effective solution, showcasing the lowest turbidity. This optimal dosage also demonstrated superior performance in colour reduction and total suspended solids in the settled solution.

It also determined that applying a larger dose than 240ppm was a waste of chemical and cost for the client.

results and benefits

Effectiveness. Effective solid-liquid separation achieved.

Optimised Efficiency. Equilibrium between chemical efficacy and cost found via scientific testing.

Compliance. Optimised solids settling resulted in the client meeting their compliance obligations.

Confidence. Scientifically developed dosing regimen gives confidence that the solution is reliable.